Introduction

After recalling the fundamental concept of aspect in philately, we will describe the aspects which may concern the stamp 0.50 F Marianne de Béquet. We will then define the 21 different aspects identified for the 0.50 F Marianne de Béquet stamp before providing statistical information about the aspects of the 0.50 F Marianne de Béquet issued in sheets.

The notion of aspect in philately

This website is dedicated to the study of a definitive stamp. This type of study must be focused on the notion of aspect such as introduced by J.J. RABINEAU in “Timbres de tous les jours”:

The modification of only one of these components generates a new aspect. If this modification is accidental, a variety is generated.

Aspects that may concern the 0.50 F Marianne de Béquet stamp

For the 0,50F Marianne de Béquet stamp, the various industrial components involved in its production are printing material, perforation, the existence or the non-existence of phosphorescent bands, the type of phosphorescent bands, paper, gum, ink and the existence or the non-existence of an overprinting.

Printing equipment

This stamp was printed on TD6 presses (cf. General information about printing on TD6 presses), TD3 presses (cf. Stamps printed on TD3 presses) and RGR presses (cf. Tests on the R.G.R. press ).

Perforation

All produced 0.50 F Marianne de Béquet stamps have the same perforation 13 x 13, made with combs (cf. [>article111#comb_1] for TD6 presses and Stamps printed on TD3 presses for TD3 presses). However, the examination of the perforation can be used to determine the origin of a stamp (sheet, booklet of 10 stamps, booklet of 20 stamps or coil) as shown in Recognition of the origin of stamps.

Existence or non-existence of phosphorescent bands

Some stamps were produced without phosphor bands for automatic mail sorting, while others were overprinted with 3 phosphorescent bands.

The type of phosphorescent bands

As will be seen in Article General information about printing on TD6 presses, there are three types of phosphorescent bands referred to A, D or B by J.J. RABINEAU.

Paper

[*] Paper is generally made from wood products such as wedges. This wood must be processed to cellulose fibres, either mechanically or chemically. Cellulose fibres are finely ground and water is added to make pulp. It is at this stage of the process that ingredients can be added to obtain special features of the paper (dye, glue primer, optical brightening...) This pulp can then be used to make paper, in large paper machines.

For the intaglio printing of stamps, a certain number of characteristics are required for the paper, which concern:

Its composition

It is mainly paper based on rags fulfilling the AFNOR VII standard that is used;

Its paper weight

The paper used has a weight of 72 g/m2/sup> (not counting gum);

Its mechanical resistance to traction and pressure

This resistance is measured by the length of rupture (length from which the paper tears when stretched) and the resistance to bursting;

Porosity

It is measured by the time it takes water to pass through half the thickness of the paper, which is defined by the degree of bonding of the paper. The degree of bonding must vary between 15 and 40 s for intaglio printing;

Printability

It depends on the surface characteristics of the paper (smoothing...);

Suitability for perforation

The paper should not be too abrasive to avoid a too rapid wear of the perforating device;

Hygrometry

In intaglio printing, the fibres of the paper must be moistened, within half the thickness of the paper, so that the paper fetches the ink at the bottom of the sizes, but not too much to prevent the gum from becoming sticky.

In philately, various types of paper have been used (with watermark, fluorescent, glazed, GC...). However, for the 0.50 F Marianne de Béquet stamp, the only known differences for the paper used concern the possible presence of optical brighteners. So we will only develop this aspect.

Human vision perceives the electromagnetic radiation of light between about 380 and 780 nm (this is the visible spectrum). Optical brighteners are molecules that absorb electromagnetic radiation between 300 and 400 nm (therefore outside the visible spectrum) to re-emit it between 400 and 500 nm (in the blues).

Natural cellulose fibres tend to absorb radiation in the blues and therefore have a yellowish appearance. A brightening agent compensates for this loss: yellow and blue colors are complementary, they neutralize each other.

Note 1: the presence of an optical brightener in a paper is only detectable through a UV lamp.

Note 2: the presence of an optical brightener in the paper used to produce stamps apparently depends on the paper supplier. Therefore, the presence or absence of optical brightening for a stamp cannot be considered as an aspect of it.

Gum

Gum is the substance affixed to the back of stamps when they are manufactured. The 0.50 F Marianne de Béquet stamp is known with two types of gum:

Acacia gum

This gum, also called metropolitan gum by philatelists, is a polymer naturally produced by some acacias of African origin. It is a substance consisting of long polymers bound by an end to paper cellulose by esters and containing unsaturated functions. These unsaturated functions have no sticky properties in the anhydride state, but the slightest presence of water catalyzes the opening of the gum unsaturations to form a second ester bond.

This gum raises storage problems under conditions of high humidity (stamp sheets stick together for example).

Tropical gum

It is a synthetic gum based on polyvinyl alcohol, for which tests are known from 1968. This gum, which does not react to humidity variations, was introduced to allow the sale of stamps using distributors, some of which could be located outside post offices. Initially reserved for coil stamps (of Cheffer type), this type of gum was extended to sheet stamps in 1972.

Printing ink

Ink is a complex mixture of three main elements:

- a colouring material, most commonly composed of very finely divided pigments, which represents 5-25% of the ink’s weight;

- an ink vehicle, which is the fluid part of ink, which makes up about 70% of its composition. It is a mixture of polymers (hard resins, vegetable oils or petroleum distillates), thinners and/or solvents. Its role is twofold: transporting and fixing the solvent onto the support;

- additives, which constitute about 10% of the final product (waxes, drying agents such as mineral salts, anti-maculant compounds...). They optimize the characteristics of ink during and after printing and are used to facilitate the implementation of ink. For intaglio printing, ink is greasy and viscous, as can be seen in the following picture:

Regarding the stamp 0.50 F Marianne de Béquet, we can show the colour chart that was used in Boulazac for this stamp:

Existence or non-existence of a 25 F CFA overprint

Before 1975, Reunion Island used the CFA franc (franc des Colonies Françaises d’Afrique) and it was therefore necessary to produce stamps in CFA francs. To this end, French stamps were used, overprinted to replace the value. These stamps were printed at the "Service des Minerves", with an additional passage on a "F.L." type ( for Foulon and Langenhagen) platen press.

A "F.L." type platen press prints only one side of the sheet. It is a flat bed press: the printing form (the metal frame holding the typesetting) and the plate are flat.

Such a press is composed of:

- a vertical fixed platen called "printer form";

- a circular tray receiving the ink. For a better distribution of the ink, the surface of this steel disc is striated and it turns a thirty-second turn at each pass. ;

- Ink rollers located above the inking plate at rest;

- a mobile plate receiving the sheet of paper to be printed which will be maintained by a racket (metal rods);

- a foot pedal activating the printing system;

- a lever located on the side to adjust the pressure of the platen on the printing form;

- possibly an electric motor for the movement to guarantee a regular pressure of the paper;

- two wooden trays to receive the sheets before and after printing.

The overloads are printed as follows:

- the sheets to be printed are placed manually horizontally on the support plate;

- the ink is first spread with a spatula on the circular plate;

- the inking rollers go down on this circular plate and take up ink;

- then they go down on the printing form to deposit the ink;

- they move up and clear the space in front of the now inked print form;

- the movable platen tilts and is pressed against the printing form when the platen comes upright (in this type of machine, the printing form and platen are linked by a hinge that allows them to open in a V-shape and close against each other, like a book);

- the agent removes the printed sheet and stores it on the wooden tray.

Type "F.L."platen press (the press and the feeder are separated)(copyright : Musée de l’Imprimerie et de la Communication Graphique)

Type "F.L."platen press (the press and the feeder are separated)(copyright : Musée de l’Imprimerie et de la Communication Graphique)

Known aspects of the 0,50 F Marianne de Béquet stamp

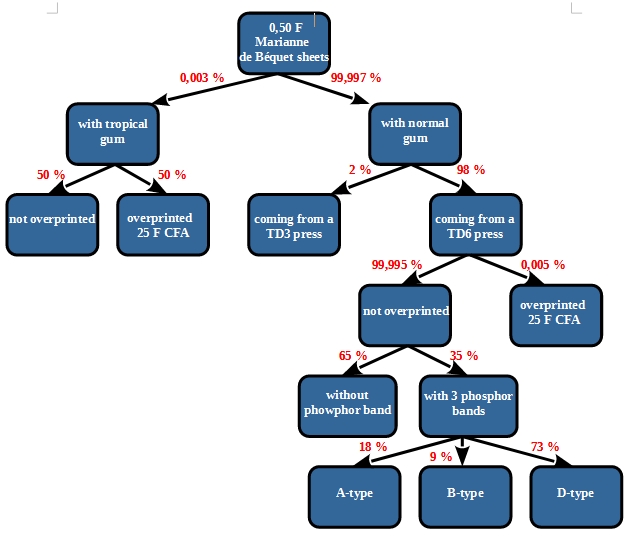

We are now going to describe the 17 known aspects of the stamp 0,50 F Marianne de Béquet with the help of a tree structure representing all the possible cases according to the known components of the aspects of the stamp 0,50 F Marianne de Béquet. Note that the 17 different aspects of this stamp represented by the leaves of the tree are colored in red.

Some statistical elements

From the number of printing days of the 0,50F Marianne de Béquet stamps from sheets (and by considering known worked Saturdays as normal days), it is possible to establish statistics on the various aspects of this stamp when it was issued in sheet form.

This tree structure gives the proportions between the various aspects of the stamp 0,50 F Marianne de Béquet issued in sheet form. Indeed, it should be noted that at the time of the Marianne de Béquet, no information on the printings in the form of booklets or rolls was provided. We do not know how many stamps were issued in booklets or coil form, and the statistics can only concern stamps issued in sheets.